Humanity

Needs New

Frontiers

Speculative Technologies is a nonprofit industrial research lab for public good. Our mission is to create an abundant, wonder-filled future by unlocking powerful materials and manufacturing technologies that don’t have a home in other institutions.

To skip to the details, check out our FAQ.

Filling gaps in the

Research ecosystem

Our ability to unlock many physical technologies has stalled because of an institutional gap between academic research and product development.

Large companies and startups need to focus on profit and growth, respectively, making them a poor home for speculative technology research: there is uncertainty both about success and whether the organization doing the work will be able to capture the value of that technology. As a result, academia has established a monopoly on pre-commercial research. But the university system that prioritizes novelty over usefulness, can’t hire engineering teams, and has some of the most intense bureaucracies in history is at odds with creating amazing new technologies.

If we don’t close this gap, the future is at stake.

New materials and

Manufacturing processes

We focus on new paradigms in materials and manufacturing. While these areas aren’t the first that come to mind when you think of the world's biggest problems, new materials and manufacturing processes consistently enable us to solve problems and create abundance in ways we couldn’t even have imagined.

We call them the bronze, copper, iron, steam, and silicon ages for a reason.

Our model is meant to bridge the “valley of death” by riffing on the things that made Bell Labs, pre-1972 ARPA, and Xerox PARC great without slavishly trying to copy 20th century organizations in the 21st century.

At the end of the day, our MO is to do what needs to be done to turn big-if-true technologies from a weird thing that seems like it will never happen into an inevitability. Obviously, that’s a bit vague so we organize around two core concepts:

Amazing program leads and coordinated research programs

Program Leads

We find ambitious scientists with deep technical expertise and a clear vision of big-if-true technologies that don’t have a home in other institutions, work with them to figure out how to build those technologies, and then help them execute on that plan.

Coordinated Research Programs

Our program leads run five-year research efforts with four phases:

Programs

Brains Coordinated Research Accelerator

Brains is a 15-week, part-time accelerator to provide the skills and opportunities for ambitious individuals to execute on research visions with potentially huge impact that aren’t a good fit for a company but are too big for a single academic lab.

Think YCombinator for coordinated research programs.

Carbon to Chemicals

Led By: Quentin Dudley

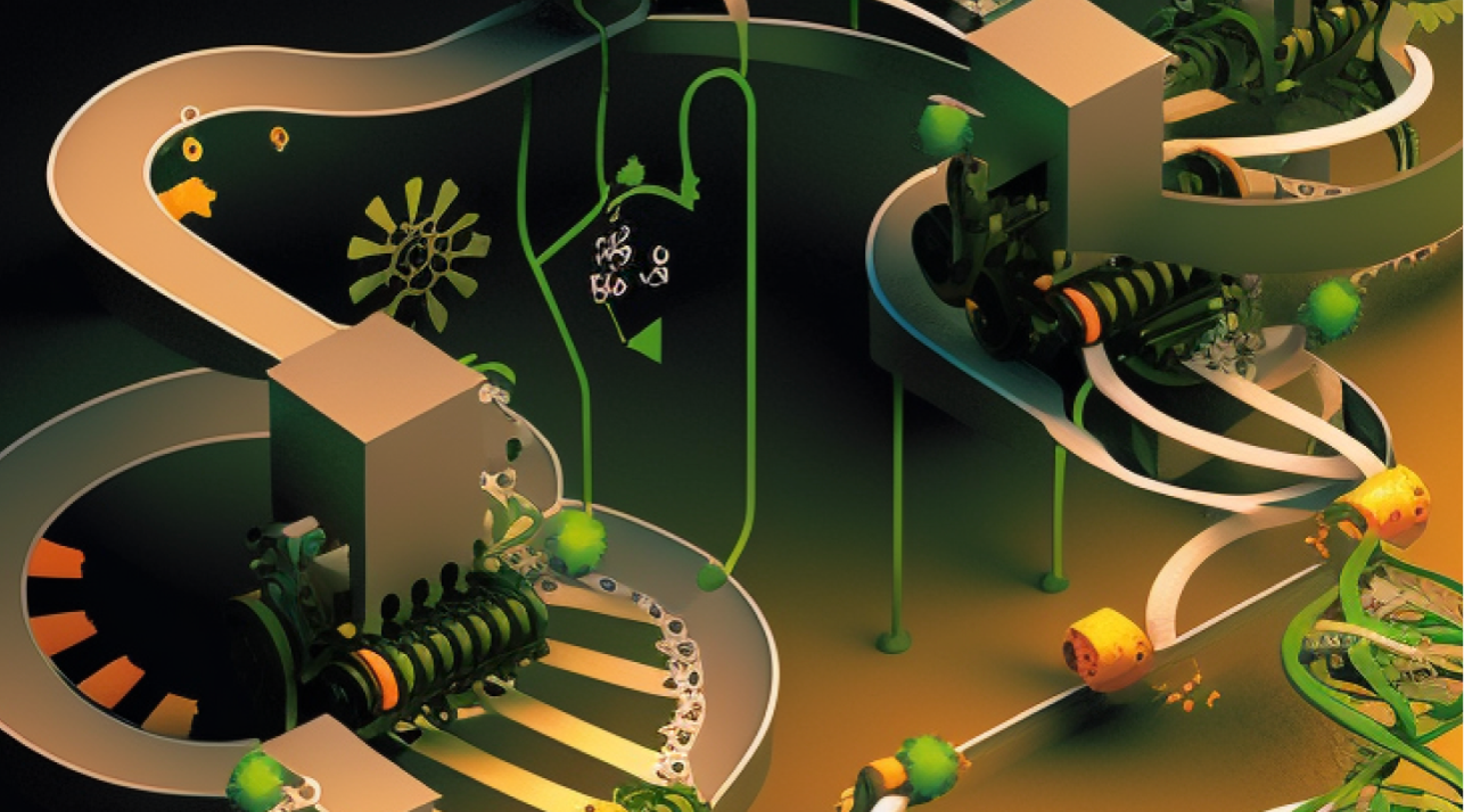

By pulling enzymes, substrates, and cofactors out of organisms and into a bioreactor, we can take advantage of metabolic pathways to sustainably convert harvested sugar or even carbon dioxide from the atmosphere into useful molecules quickly and efficiently instead of deriving them from petroleum.This program aims to expand the scale and scope of cell-free manufacturing, both of which are currently limited.

Impossible Fibers

Led By: Tim McGee

Natural materials, like spider silk, dramatically outperform synthetic materials in multiple dimensions.

It might be possible to build systems that use the same mechanisms as biology to build high performance fibers and materials that are currently unachievable while simultaneously making existing processes more sustainable.

Nanomodular Electronics

Led By: Michael Filler

Nanomodular electronics is creating a new process for manufacturing microelectronics that are customizable down to the transistor, use a plethora of materials, and can be made on-demand without etching silicon or requiring a massive, expensive facility. By creating tiny, modular components separately from laying them down and wiring them together, we could make custom microelectronics as easily as printing this document.

Molecular Additive Manufacturing

Led By: Chris Wintersinger

Molecular additive manufacturing is creating heterogeneous materials whose structures can be specified down to nanoscale building blocks, potentially enabling us to engineer structures we depend on biology for today. By templating a precise pattern of covalently bonded proteins, polymers, and inorganic molecules, we could create powerful catalysts, membranes to easily filter water, and take the first steps on the path towards atomically precise manufacturing.

ARIA Collaboration

Spectech is creating a soon-to-be-public library of resources on how to run coordinated research programs, in collaboration with the UK’s ARIA (Advanced Research + Invention Agency). We believe that it’s possible to make this career more accessible by codifying the critical skills and mindsets that go into leading these programs. We are also creating a complementary 1:1 mentoring program for ARIA’s programme directors.

Programs

Brains Coordinated Research Accelerator

Brains is a 15-week, part-time accelerator to provide the skills and opportunities for ambitious individuals to execute on research visions with potentially huge impact that aren’t a good fit for a company but are too big for a single academic lab.

Think YCombinator for coordinated research programs.

Carbon to Chemicals

Led By: Quentin Dudley

By pulling enzymes, substrates, and cofactors out of organisms and into a bioreactor, we can take advantage of metabolic pathways to sustainably convert harvested sugar or even carbon dioxide from the atmosphere into useful molecules quickly and efficiently instead of deriving them from petroleum.This program aims to expand the scale and scope of cell-free manufacturing, both of which are currently limited.

Impossible Fibers

Led By: Tim McGee

Natural materials, like spider silk, dramatically outperform synthetic materials in multiple dimensions.

It might be possible to build systems that use the same mechanisms as biology to build high performance fibers and materials that are currently unachievable while simultaneously making existing processes more sustainable.

Nanomodular Electronics

Led By: Michael Filler

Nanomodular electronics is creating a new process for manufacturing microelectronics that are customizable down to the transistor, use a plethora of materials, and can be made on-demand without etching silicon or requiring a massive, expensive facility. By creating tiny, modular components separately from laying them down and wiring them together, we could make custom microelectronics as easily as printing this document.

Molecular Additive Manufacturing

Led By: Chris Wintersinger

Molecular additive manufacturing is creating heterogeneous materials whose structures can be specified down to nanoscale building blocks, potentially enabling us to engineer structures we depend on biology for today. By templating a precise pattern of covalently bonded proteins, polymers, and inorganic molecules, we could create powerful catalysts, membranes to easily filter water, and take the first steps on the path towards atomically precise manufacturing.

ARIA Collaboration

Spectech is creating a soon-to-be-public library of resources on how to run coordinated research programs, in collaboration with the UK’s ARIA (Advanced Research + Invention Agency). We believe that it’s possible to make this career more accessible by codifying the critical skills and mindsets that go into leading these programs. We are also creating a complementary 1:1 mentoring program for ARIA’s programme directors.